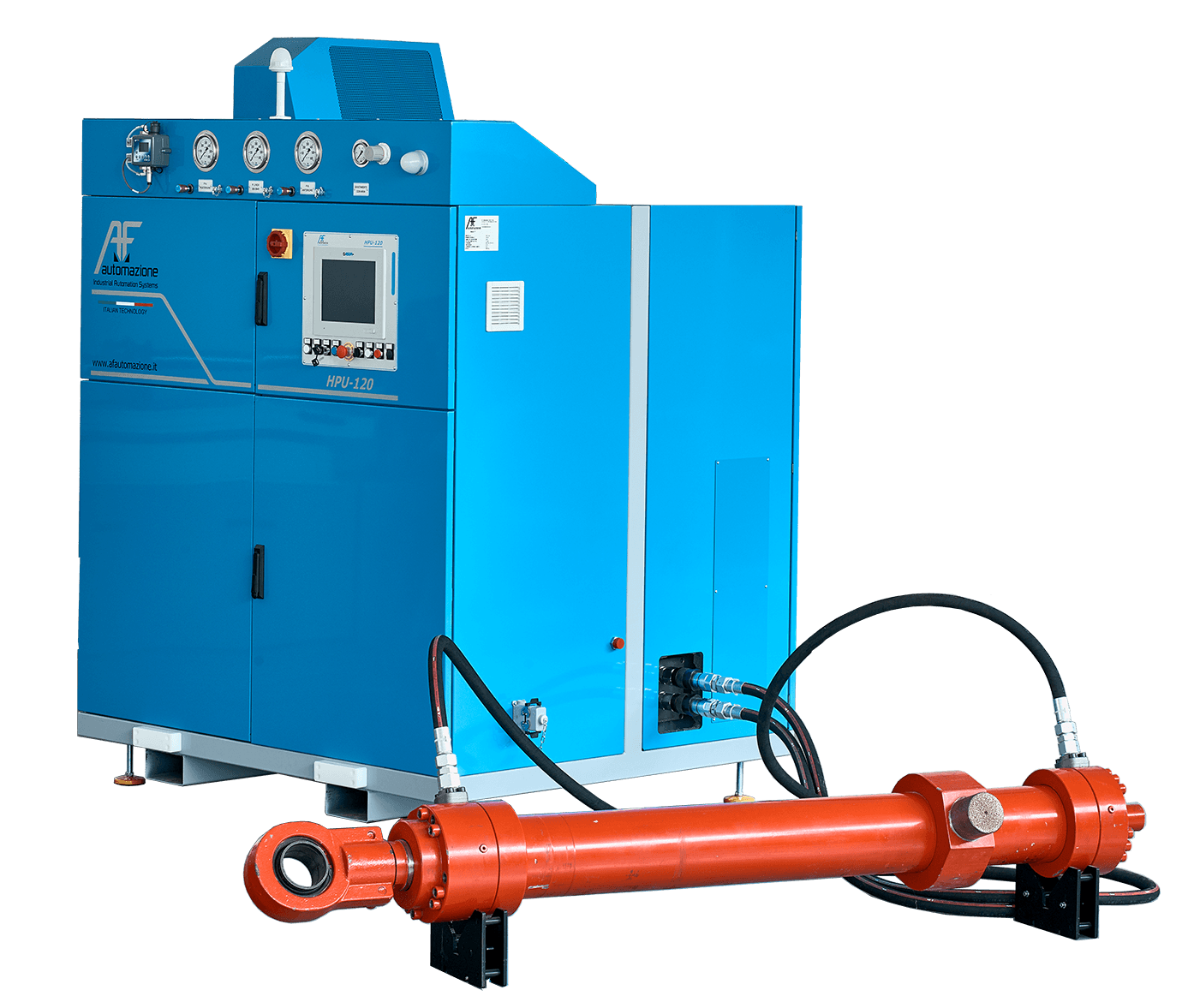

The Hydraulic Power Unit

the heart of the machine

The hydraulic power unit is the starting point of an already very advanced test-station; It allows the cylinders to be tested in order to certify their quality and performance.

The HPU (Hydraulic Power Unit) can be in future easily integrated with other equipment: such as the support bench, assembly group, and other optional devices in order to achieve higher production standards, and almost zeroing the number of returns for non-compliance of product.

HPU is equipped with an industrial PC and the software for cylinder testing and it is extremely useful by itself, stand alone. Your testing machine can be customized with maximum pressures applied up to 350/500/700 bar.

The tests that can be performed by the HPU are the following:

- Air test

- Flushing

- Low pressure test

- High pressure test

- Pressure test of equivalent chambers

- Stress test

Certify the quality of your production is the winning choice to be competitive in the today’s market.

Power with control, heart in synchrony with the mind.