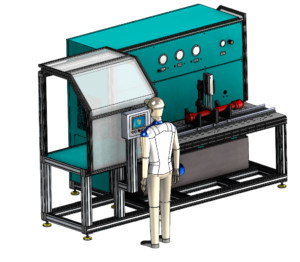

Our assembly and test benches are just the right tools you were looking for, to speed up and simplify both the assembly and testing phases when producing or repairing your hydraulic cylinders. The project has the aim to decrease overall manual operations and to assure higher safety standard level in the working environment. In order to reduce the cycle time and improve the performance of your cylinders and productivity at your company, choose our Italian Technology Systems.

Improve productivity

Every system is designed to reduce downtime. Two hydraulic vices block the cylinder. Their geometry is designed to fit different cylinders diameters. Flexible pipes with quick coupling allow linking cylinder to hydraulic circuit quickly. The automatic cycle, reduces the tasks carried out by the operator.

Choose to deliver the best quality

The testing cycle is parametric and automatic. The oil property (temperature, humidity, contamination level) are measured during the test with sensors, transducers and a special device called ICM (IN-Line Contamination Monitor). This sophisticated system guarantees the test reliability and repeatability. You can customize the test method depending on the current regulation (e.g. UNI ISO 10100:2001) of the country where the cylinder will be sold.

Security

Every system respect the European Machinery Directive 2006/42/CE and the EI EN 60204-1 (Safety of machinery – Electrical equipment of machines) in order to preserve the operator safety.

BAT-H 20 BASIC

A compact and easy to use model of bench: BAT-H 20 BASIC. It has a basic equilibrium between testing and the performance needs for your hydraulic cylinders.

BAT-H 15 COMPACT

This bench is the best tool to test and assemble small cylinders. This bench can be easily equipped with numerous optional to increase the tests that you require to do on the hydraulic cylinders.

BAT-H 15 TWIN

This model is designed as a double work station for one or two operators, in order to reduce the assembly and testing cycles time of small cylinders. The two work stations allow you to place a cylinder on one side while you’re running the test cycle on the other side. The hydraulic unit and the control system are unique for both stations.

The bench model Bat-h 15 Twin is suitable for companies who aim to obtain faster assembly working time, avoiding the waste of gaskets, top quality assured by test reports about the performance of your hydraulic cylinders.

BAT-H 35 SERIES

The BAT-H 35 series of benches are heavy structured machines designed to assemble and test medium and big cylinders. All optional can be added to meet your companies’ requirements.

Cart system – Rod introducer

On most of the heaviest benches these moving structure, the shuttle to assemble and introduce the rod can be integrated and has two main functions: it can be used in place or to assemble the rod with the cylinder’s head and the piston as its movement can be employed “to have the heavy displacement work done”. The shuttle is the right tool for sticking up to safety standards and having a controlled assembling, this tool can be paired with bench models of the BAT-H 35 series.

BAT-H 35-4

This model bench is the best tool to assemble and test hydraulic cylinder up to 400 mm of external diameter. All optional can be added to meet your companies’ requirements.

BAT-H 35-6

The BAT-H 35-6 model is the best tool to assemble and test hydraulic cylinders up to 600 mm of external diameter. Again, whatever your special needs may be, optional can be added and customized very in detail.

BAT-H 35-7

The BAT-H 35-7 model is a heavy and multifunctional tool to assemble and test big hydraulic cylinders up to 700 mm of external diameter.

BAT-H 35 10

This bench, until now, is the heaviest the most resistant structure we’ve delivered on the market. This machine is useful to assemble and test hydraulic cylinders up to 1000 mm of external diameter.

Many optional can be part of the final machine, to meet your company’s needs.

“Every bench is a custom project”

“Every bench is a custom project”

We Create Automation Around our Customers’ Requirements